Optimize Warehouse Value Added Services with Python

Use Linear Programming to Increase your Production Capacity for the Final Assembly of Luxury Products

Use Linear Programming to Increase your Production Capacity for the Final Assembly of Luxury Products

Article originally published on Medium.

Most of the challenges faced by Distribution Centers (DC) handling Luxury Products, Garments or high-value goods are during Inbound Process.

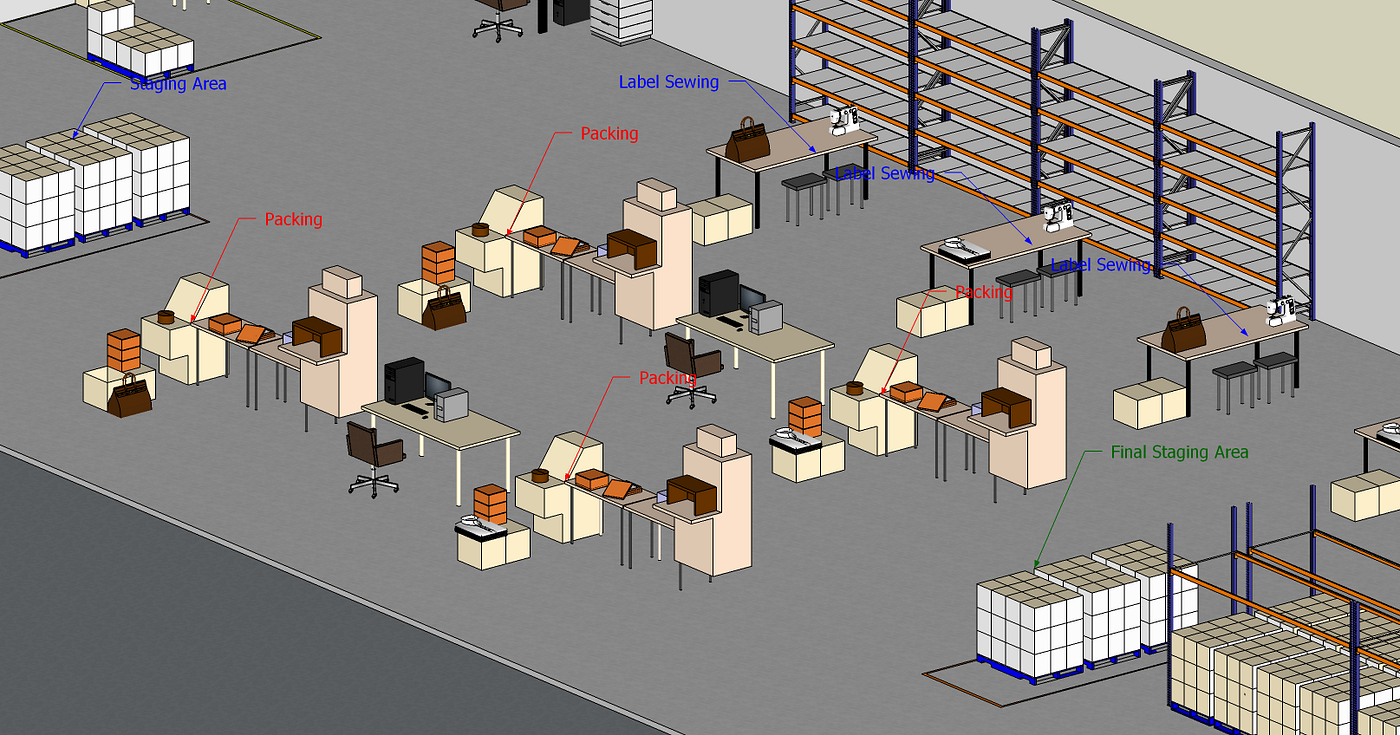

We will take the example of a DC storing imported Luxury Bags, Garments and Shoes that need:

- Machine 1 — Anti-theft tag: put a self alarm tag to protect your goods against theft in the store

- Machine 2 — Labelling: print labels in the local language and perform label sewing

- Machine 3 — Kitting & Repackaging: transfer your goods in the sales packaging and add Gift With Purchase (GWP), Individual Note or Certificate of Authenticity

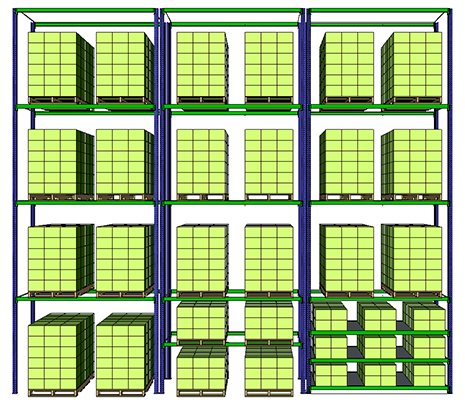

After completing these 3 steps, your goods are ready to be put away in the stock area and are waiting to be picked up for shipping to their final destinations (Store).

If your capacity of items handled by day is too low, this process can quickly become a major bottleneck.

💌 New articles straight in your inbox for free: Newsletter

Problem Statement

Scenario

You are an Inbound Manager of a Distribution Center (DC) for an iconic Luxury Maison focusing on Fashion, Fragrance and Watches.

You have received 600 prêt-à-porter sets (Ready-to-wear) including:

- 1 Female dress that requires Label Sewing and Re-packing

- 1 Handbag that requires Label Sewing, an Anti-theft tag and Re-packing

- 1 Leather Belt that requires an Anti-theft tag, Label Sewing and Re-packing

Because they are sold together, these SKUs need to be ready at the same time and co-packed together to be ready for shipping to stores as soon as possible after the following steps:

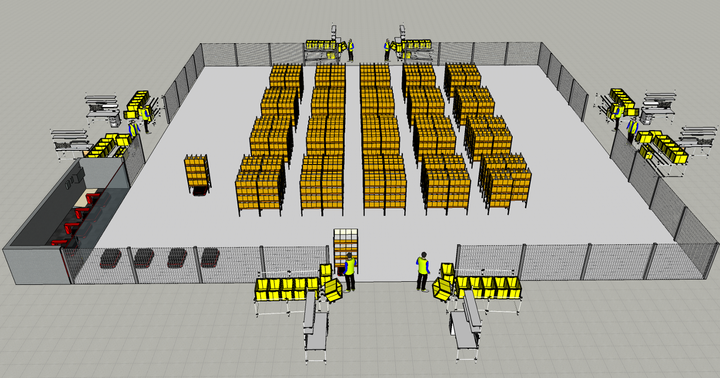

- Inbound Team is unloading pallets from the truck and putting them in the staging area

- Machine 1: Anti-theft tag — an operator put an anti-theft tag on each bag and belt

- Machine 2 — Labelling: after printing in a dedicated area, labels are sewed on belts, handbags and dress

- Machine 3 — Kitting & Repackaging: for each item, you need to add a certificate of authenticity, plastic protection and perform fine packing

After the re-packaging process, goods are transferred to a final staging area to wait for shipping (X-Docking Mode).

Objective: Reach maximum productivity of sets assembled per hour (sets/hour)

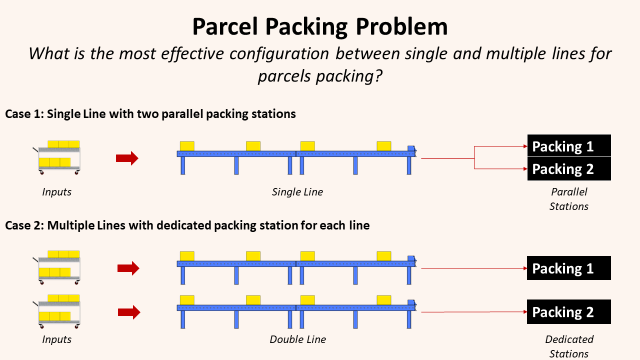

2. Problem Statement: The Job-Shop Problem

The Job Shop Scheduling Problem (JSSP) is an NP-hard problem defined by a set of jobs that must be executed by a set of machines in a specific order for each job.

For each of our jobs, we have defined the execution time (min) and processing order of machines in the table above.

For instance, Job 2 (Handbag) is starting with Anti-theft Tags placement using Machine 1 (6 min) followed by Labels Sewing using Machine 2 (4 min), to finally end with Kitting and Packing using Machine 3 (3 min).

The machines can only execute one job at a time. And once started, the machine cannot be interrupted until the completion of the assigned job.

Objective: minimize the makespan, i.e the total time for completion of all jobs

i. The Naive Solution: 1 job cycle at a time

Results

- Makespan: 30 min

- Productivity: 2 sets/hour

Comments

This simple approach is the worst in terms of productivity. Because of the processing of jobs in sequence, machines stay idle (unused) quite often.

Question: What would be the result if we performed jobs in parallel?

ii. Optimal Solution: The Job Shop Scheduling Problem using Google OR-Tools

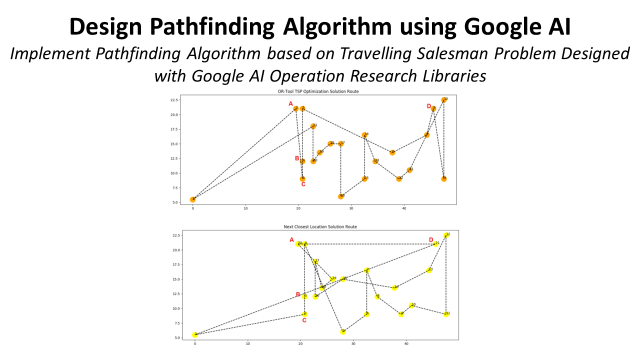

OR-Tools is an open-source collection of Google with tools for combinatorial optimization. The objective is to find the best solution out of a large set of possible solutions.

I am a fan of this library that I have been using in several examples:

- Design a Pathfinding Algorithm using Google AI to Improve Warehouse Productivity

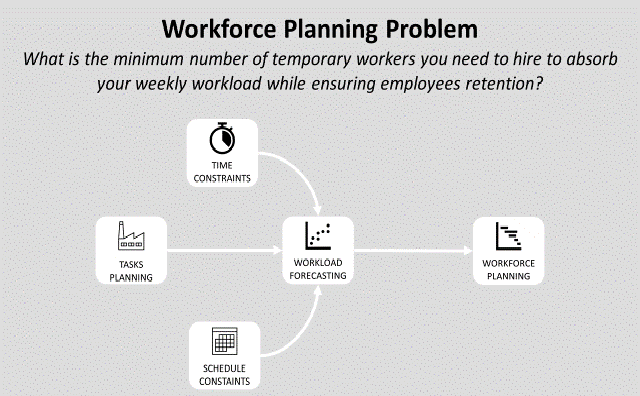

- Optimize Workforce Planning using Linear Programming with Python

Let us use this library to find the optimal sequencing to reduce the makespan for this specific set of processes.

Optimization of your Scheduling

Results: Optimized vs. Naive Solutions

You can see the two graphs above representing the initial solution (Naive Solution: 1 job at a time) and the Optimized Solution (Parallel Tasking).

Results

- Total Makespan: 16 min (-47%)

- Productivity: 3.75 sets/hour (+85%)

- Idle time per cycle: 18 min (-71.4%)

The results are satisfying

I will explain how to reach these results now.

Edit: You can find a Youtube version of this article with animations in the link below.

Build the optimization model

Initialize your model

Three, machines

Total Time using Naive Solution: 30 min

b. Initialize variables and create sequences

c. Add Constraints and Set up the Solver

d. Solver Optimal Solution

Based on this output, we can draw the updated schedule:

Conclusion & Next Steps

Conclusion

We increased productivity by +48% by implementing a solution for smart scheduling that uses the maximum potential of our resources (Machines).

This solution was based on a simple scenario using a single line of assembly (1 Machine per Type).

Question: What could be the results with several lines?

I let you test it and share your results (or questions) in the comment area.

Next Steps

Can we have higher productivity by changing the conditions?

In the chart above, I have highlighted the potential additional jobs we could add during the idle time:

- Machine 1: 1 sequence of 4 min, which equals the time for Job 3

- Machine 2: 1 sequence of 4 min, which equals the time for Job 1 and Job 2

- Machine 3: 2 sequences of 4 min, which equals the time for Jobs 1,2 and 3

Question: What would be the average productivity if we start Jobs of Cycle n+1 during these idle sequences of Cycle n?

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, please contact me.

References

[1] Google AI, Google OR-Tools Library, Link