Improve Warehouse Productivity using Order Batching with Python

Design a simulation model to estimate the impact of several Single Picker Routing Problem strategies in your Picking Productivity

Design a simulation model to estimate the impact of several Single Picker Routing Problem strategies on your Picking Productivity

Article originally published on Medium.

In a Distribution Center (DC), walking time from one location to another during the picking route can account for 60% to 70% of the operator’s working time.

Reducing this walking time is the most effective way to increase your DC overall productivity.

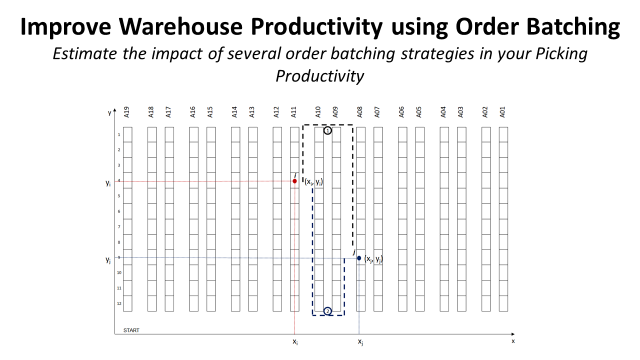

This series of articles aims to determine how to design a model to simulate the impact of several picking processes and routing methods to find optimal order picking by using the Single Picker Routing Problem (SPRP) for a two-dimensional warehouse model (axis-x, axis-y).

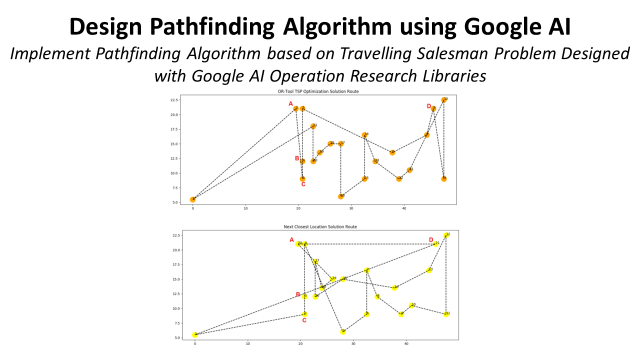

SPRP is a specific application of the general Traveling Salesman Problem (TSP) answering the question:

“Given a list of storage locations and the distances between each pair of locations, what is the shortest possible route that visits each storage location and returns to the depot ?”

SPRP is used to determine the minimum route in the picking process to prepare one or several orders.

What is Wave Picking?

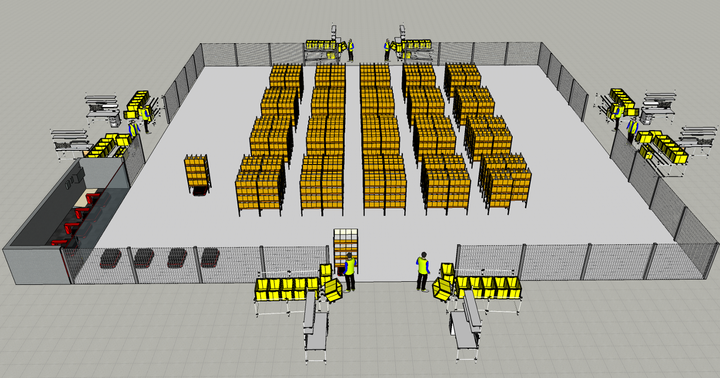

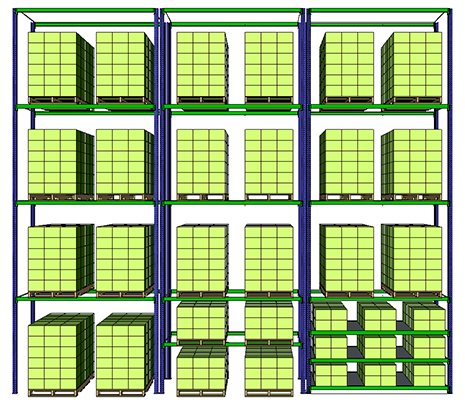

For this study, we will use the example of E-Commerce type DC where items are stored on 4 level shelves. These shelves are organized in multiple rows (Row#: 1 … n) and aisles (Aisle#: A1 … A_n).

Assumptions

- Items Dimensions: Small and light dimensions items

- Picking Cart: lightweight picking cart with a capacity of 10 orders

- Picking Route: Picking Route starts and ends at the same location

Scenario 1, the worst in terms of productivity, can be easily optimized because of

- Locations: Orders #1 and #2 have common picking locations

- Zones: orders have picking locations in a common zone

- Single-line Orders: items_picked/walking_distance efficiency is very low

The first intuitive way to optimize this process is to combine these three orders in one picking route — this strategy is commonly called Wave Picking.

Learn more about Picking Productivity

We will build a model to simulate the impact of several wave [icking strategies in the total walking distance for a specific set of orders to prepare.

Test several Optimization Algorithms

Warehouse Layout with storage location mapping

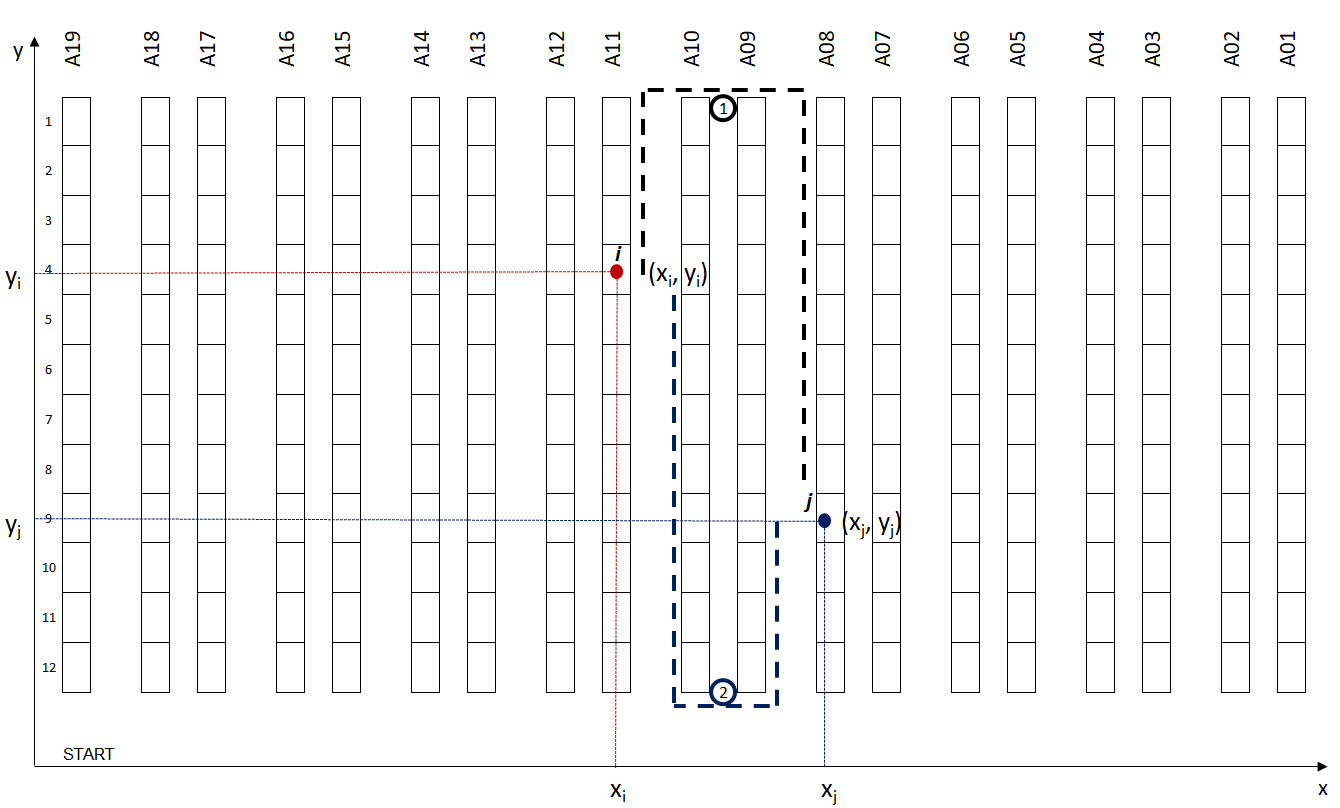

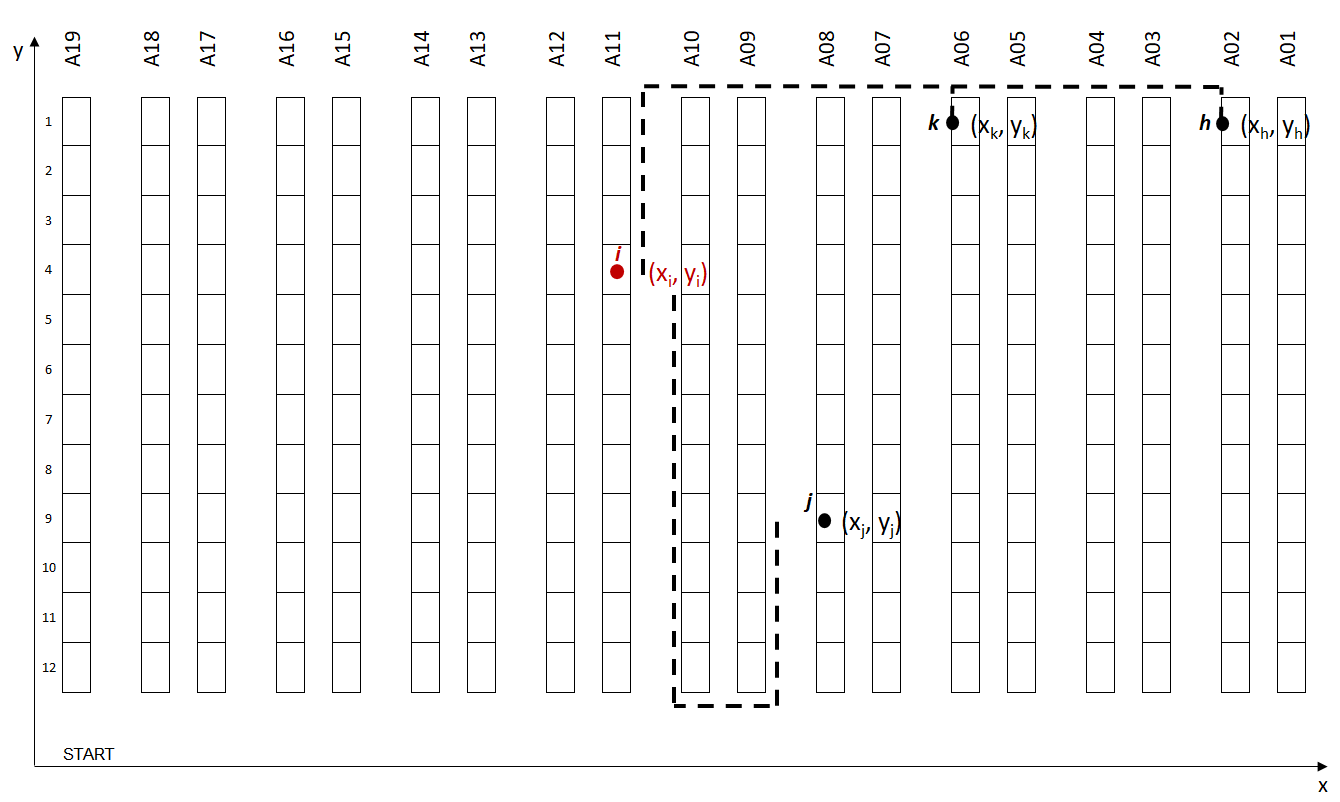

Based on the actual warehouse layout, storage locations are mapped with 2-D (x, y) coordinates that will be used to measure walking distance.

Every storage location is linked to a Reference using Master Data. (For instance, reference #123129 is located in coordinate (xi, yi)). You can then link every order line to a geographical location for picking.

Order lines from your Warehouse Management System WMS

Order lines can be extracted from your WMS Database.

This table should be joined with the Master Data table to link every order line to a storage location and its (x, y) coordinate in your warehouse.

Extra tables can be added to include more parameters in your model like (Destination, Delivery lead time, Special Packing, ..).

Functions for calculating Picking Route distance

Function 1: Calculate the distance between two picking locations

This function will be used to calculate the walking distance from a point i (xi, yi) and j (xj, yj).

Objective: return the shortest walking distance between the two potential routes from point i to point j.

Parameters

y_low: the lowest point of your alley (y-axis)

y_high: highest point of your alley (y-axis)

Code

Function 2: The Next Closest Location

This function will choose the next location among several candidates to continue your picking route.

Objective: return the closest location as the best candidate

(**) We will see later that this choice will impact overall productivity.

Code

Function 3: Create your picking route and calculate the total walking distance

This function will create your picking route from a set of orders to prepare.

- Input: a list of (x, y) locations based on items to be picked for this route

- Output: an ordered sequence of locations covered and total walking distance

Code

4. Functions for creating order waves

Function 1: Create batches of n orders to be picked at the same time

- Input: order lines data frame (df_orderlines), number of orders per wave (orders_number)

- Output: data frame mapped with wave number (Column: WaveID), the total number of waves (waves_number)

Code

Function 2: listing picking locations of wave_ID picking route

- Input: order lines data frame (df_orderlines) and wave number (waveID)

- Output: list of locations i(xi, yi) included in your picking route

Code

Results and Next Steps

Results

After setting up all necessary functions to measure picking distance, we can now test our picking route strategy with picking order lines.

Here, we first decided to start with a very simple approach

- Orders Waves: orders are grouped by chronological order of receiving time from OMS ( TimeStamp)

- Picking Route: The picking route strategy follows the Next Closest Location logic

To estimate the impact of wave picking strategy on your productivity, we will run several simulations with a gradual number of orders per wave:

- Measure Total Walking Distance: How much of the walking distance is reduced when the number of orders per route increases?

- Record Picking Route per Wave: recording the sequence of locations per route for further analysis

Code

2. Next Steps

This solution is far from being the most optimal

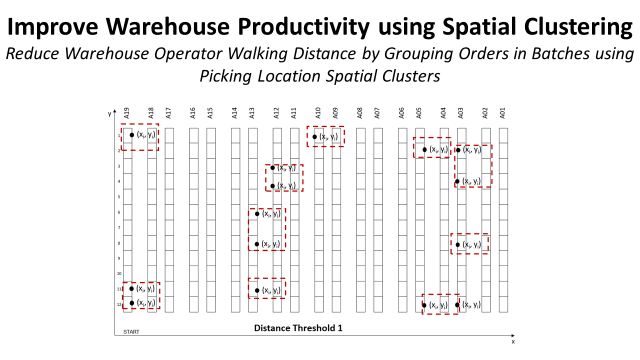

- Orders can be grouped by geographical clusters of Picking Locations to reduce pickers’ walking distance

- The Next Closest Location strategy has its limits that can be easily pointed out by picking route records.

In the next part, we will conduct a detailed analysis of this first solution to understand the limits and how we can improve them.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.