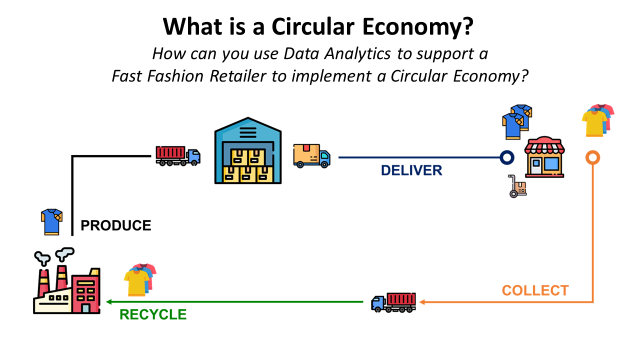

What is a Circular Economy?

How can you use Data Analytics to support a Fast Fashion Retailer to implement a Circular Economy?

How can you use Data Analytics to support a Fast Fashion Retailer in implementing a Circular Economy?

This story has been originally published on Medium.

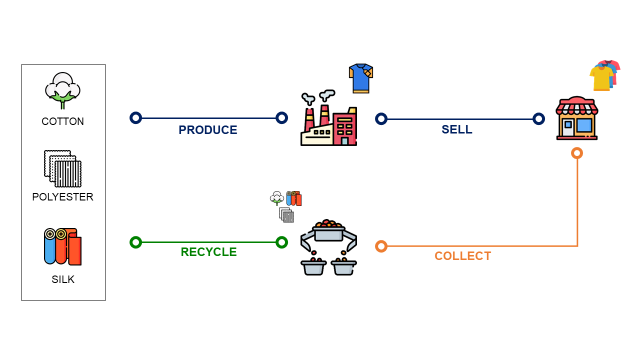

A circular economy is an economic system in which resources are used, reused, and recycled in a closed loop, instead of being extracted, used, and discarded as waste.

The aim is to maximize the usage of resources and to recover and regenerate products and materials at the end of each life cycle.

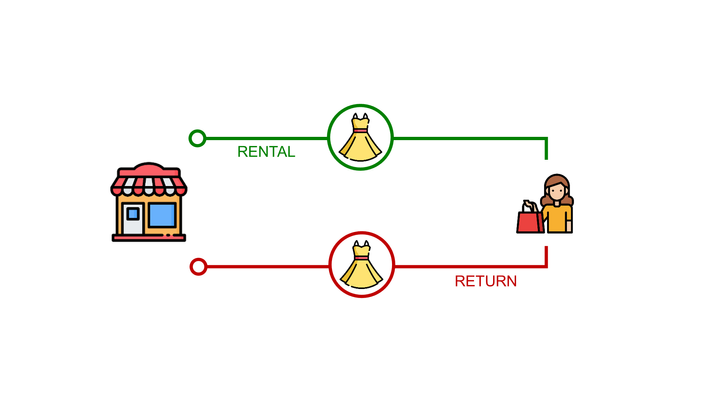

What happens to the old clothes you return to your favourite fast-fashion retail store?

They are collected and sorted into three different categories

- Wearable clothes: they will be resold as second-hand clothing.

- Reused Clothes: These will be turned into other products, such as “remake collections” or cleaning clothes.

- Recycle clothes that will be shredded into textile fibres and used to make for example, insulation materials

.This requires a major transformation of your logistics and supply chain operations to include this process in the value chain.

This article will show how data analytics can support this transformation by providing visibility and diagnostic and collaboration tools.

💌 New articles straight in your inbox for free: Newsletter

A Supply Chain Transformation

,

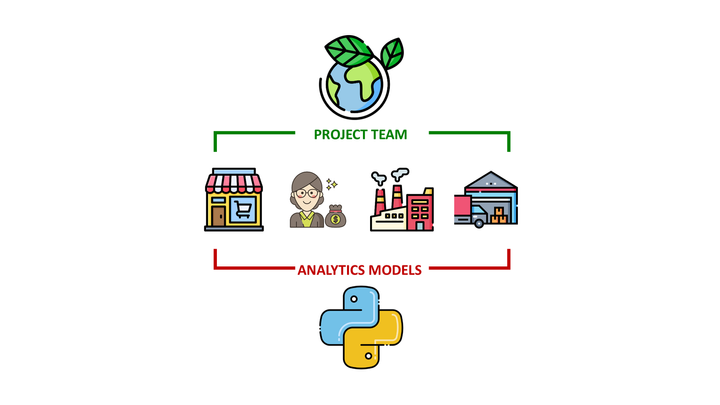

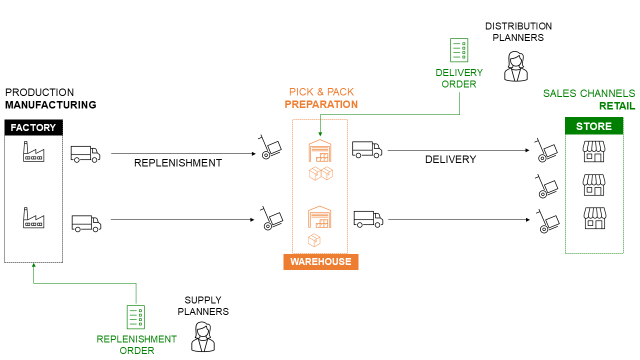

You are a logistic performance manager in an international clothing group that has stores all around the world.

The company produces garments, bags and accessories in factories located in Asia.

Stores are delivered from local warehouses that are directly replenished by factories.

In order to support the transition to a circular economy, the sustainability management asks for your support in implementing a set of processes to

- Support your customers to drop their used clothes and textiles in “collecting boxes” at your stores

- Organize the transfer of these boxes to a central warehouse using low-emissions trucks

- Implement value-added services processes with your 3PL to sort the items into the three categories for further processing.

As the focus here will be on the logistics management point of view, we will not enter into the details of the recycling processes.

What are the logistics needs?

If your company were to implement a circular economy, there would likely be several needs for logistics management.

Reverse logistics Management

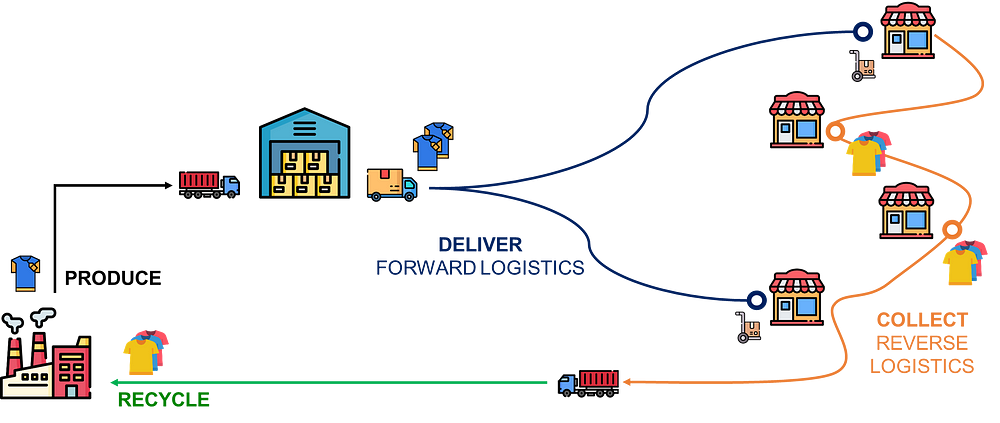

Implementing this closed loop would require the ability to collect and process used or returned products for remanufacturing, repair, or recycling.

Therefore, your team has to implement logistics systems and processes that are able to handle the reverse flow of goods.

Your team is already managing forward logistics operations that deliver new garments to the stores from your distribution centres.

💡 Supply Chain Management Challenges

- Integrate new processes and stakeholders in the Logistics Chain (Sorting Centers, Recycling Plants, Collection Boxes)

- Manage unknown products with limited information: as you accept clothes from other brands that are not in your master data you have no information about their size, weight, …

- Additional inventories and storage space needed in your stores

- Additional efforts of route planning to organize the pick-up of used clothes at the store

N.B: You can integrate this process in an ,existing procedure for stores or e-commerce conventional returns (without the recycling part).

🚚 Logistics Transformation Needs

- Manage the dedicated inventory of collected used garments at the stores (Quantity, Store Location)

- Organize the pick-up at stores and the delivery to the sorting centre (items will be sorted into 3 different categories) using electric trucks

- Manage the operations at the sorting centres

- Organize the transportation after sorting for the next steps

📉 Support of Data Analytics

- Inventory Management: you can create dedicated virtual storage locations in your system to monitor the quantity collected in your stores (in pieces, kilograms or cubic meters)

- Route Planning: using store inventory data, you can design optimal transportation plans to maximize the quantity collected per km driven (CO2 emissions reduction)

- Build forecasting and optimization models to plan your sorting operations based on the current and past volumes of items collected.

Product tracking and traceability

The regulations and internal quality rules are required to ensure that products are being used and processed in the most sustainable way possible.

Therefore, your teams need to be able to track and trace products throughout their lifecycle.

📉 Support of Data Analytics

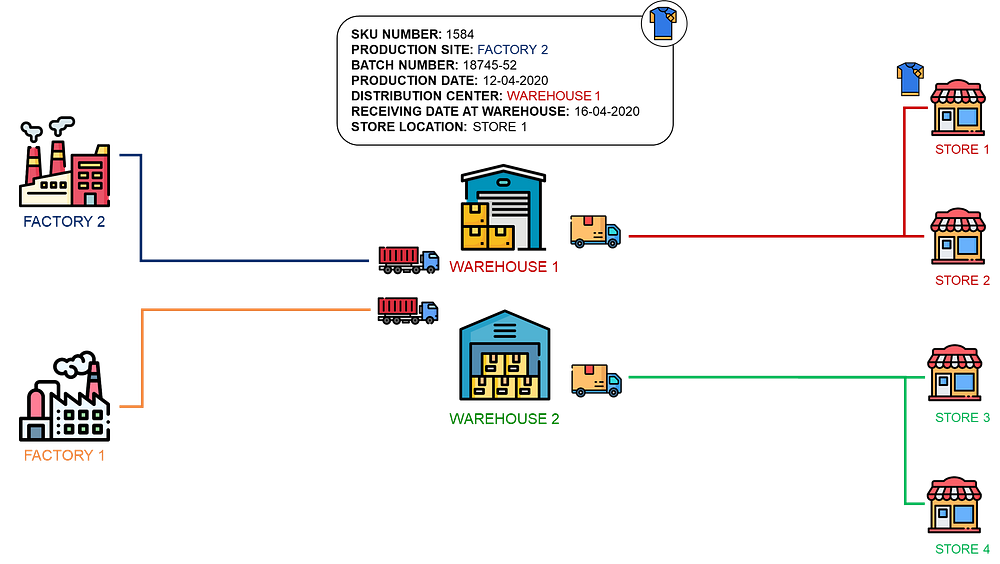

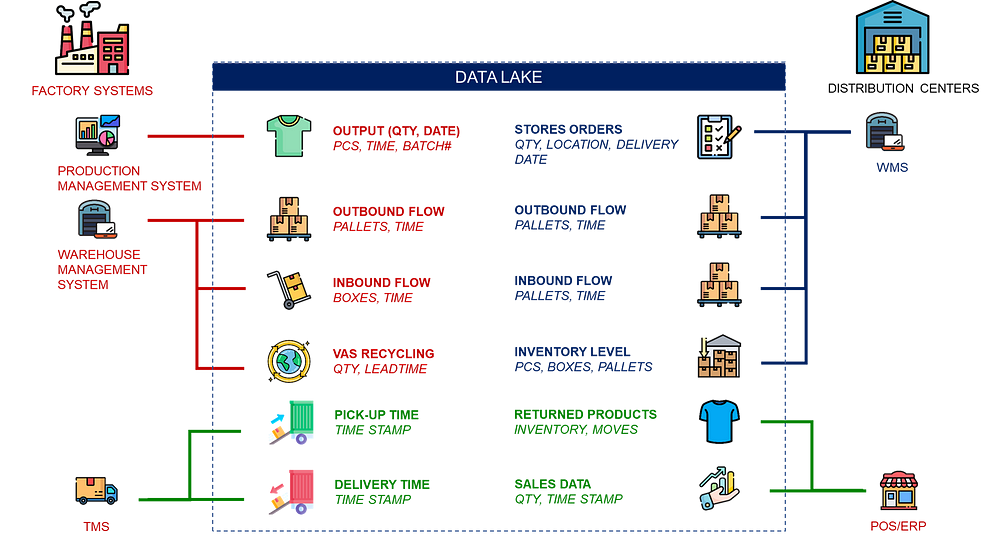

For forward logistics, products can be tracked and traced from the factory to the store delivery.

- Master data will include (Stock Keeping Unit) SKU Number, product information (size, colour, packaging)

- Production Systems can provide the batch number (very useful if you need to call items), production date, factory location.

- Warehouse and Transportation Management systems can track the product along the logistics chain from warehouse receiving, shipping, transportation and store delivery.

For reverse logistics, you can also track these “unknown” products from the collection box to the sorting centre.

- As they may not exist in your systems as an SKU when collected (except for the clothes of your brand),. you can find alternative ways of tracking using the collection box identification number, weight, or the collection batch (Box Number + Store Location + Collection Date)

- You can track quantities instead of items: number of boxes, pieces or weight.

From a logistics management point of view, you mainly need to monitor the flows to allocate resources and optimize the routing.

But the objective here may be different for your colleagues in the sustainability department:

- Do they need to be able to track from which collected item (Collection Date, Store Location, …) a reused garment is coming?

- Do they need to know the details of the items collected to produce a batch of recycled raw material?

Everything is possible if you implement the right process(es) for data capture, processing and transfer among the different systems.

Network optimization

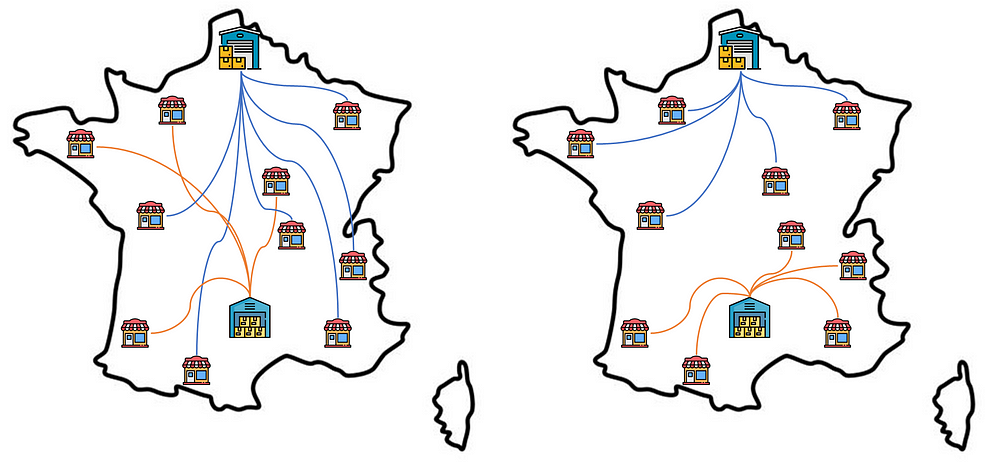

Because your company would like to minimize the environmental impact of these additional constraints, you will need to optimize the distribution network.

As you need to collect items after sales and reintroduce locally recycled materials in the production chain, the optimal network may be different from your current one.

🚚 Logistics Transformation Needs

- Limit the impact on the logistic costs: the target is to have the additional cost of transportation and sorting paid by the savings of raw material

- Mutualize the resources with the forward logistics: the trucks used to deliver the stores can also collect used items on the same routes

- Minimize the environmental impact: by reducing the distance between stores and sorting centres, use electric or low-emissions trucks

📉 Support of Data Analytics

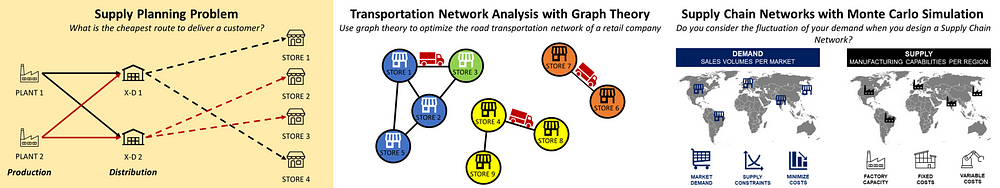

- Supply Planning Problems can be used for allocating stores to the right sorting centre (minimize distance, CO2 emissions or transportation costs)

- Transportation Network Analysis can be used to plan the collection routes to maximize the number of stores visited per route.

- Supply Chain Network Design methodologies can be used to find the optimal location of your sorting centres considering the upstream flow from the stores and the downstream flows to the distribution centres or factories.

How and Why?

A Supply Chain can be defined as several parties exchanging flows of material, information or money resources with the ultimate goal of fulfilling a customer request.

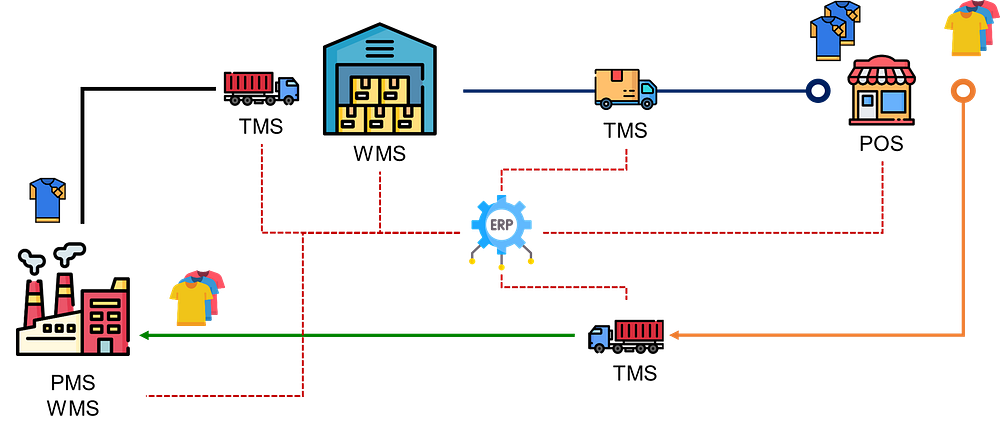

To exchange and store information, these parties use different systems:

- Transportation Management Systems (TMS)

- Point-of-sales (POS) Systems to manage sales data

- Warehouse and Production Management Systems

They may be (or not) connected to a central Enterprise Ressources Planning (ERP) system that centralizes the end-to-end operations.

If you implement a data architecture using a data lake connected to these systems, you can collect, process and analyze a set of metrics and KPIs centrally to monitor your closed-loop operations (Produce, Deliver, Sell and Recycle).

Why?

To track the progress of the circular economy implementation and make adjustments as needed, logistics management would need to be able to analyze data on product flows, logistics and recycling performance, and costs.

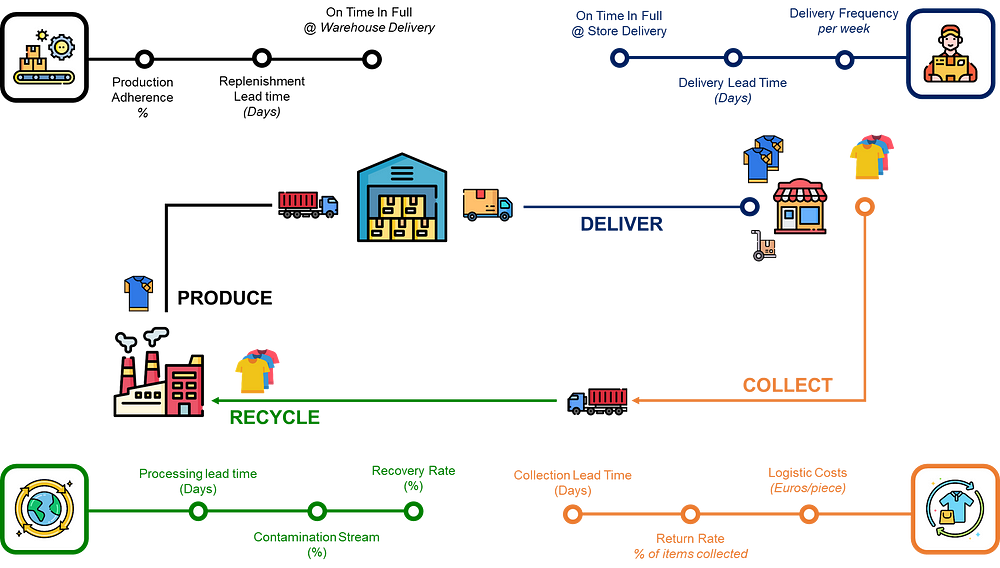

For example, you can track Key Performance Indicators (KPIs) for

Logistics Performance

- Transportation lead times for replenishment, delivery and collection

- Warehousing costs per box

- Transportation costs per Pallet

- On Time In Full (OTIF) at warehouse and store delivery

Production and recycling performance

- Production adherence: % of quantity produced / quantity planned

- Recovery rate: % of recyclable materials that are successfully recovered and processed in the recycling process

- Contamination rate: % of non-recyclable materials that are found in the recycling stream

- Processing lead time: The time and resources required to process a given amount of recyclable materials.

Conclusion

These additional constraints would require effort and resources to transform your organization and implement new tools.

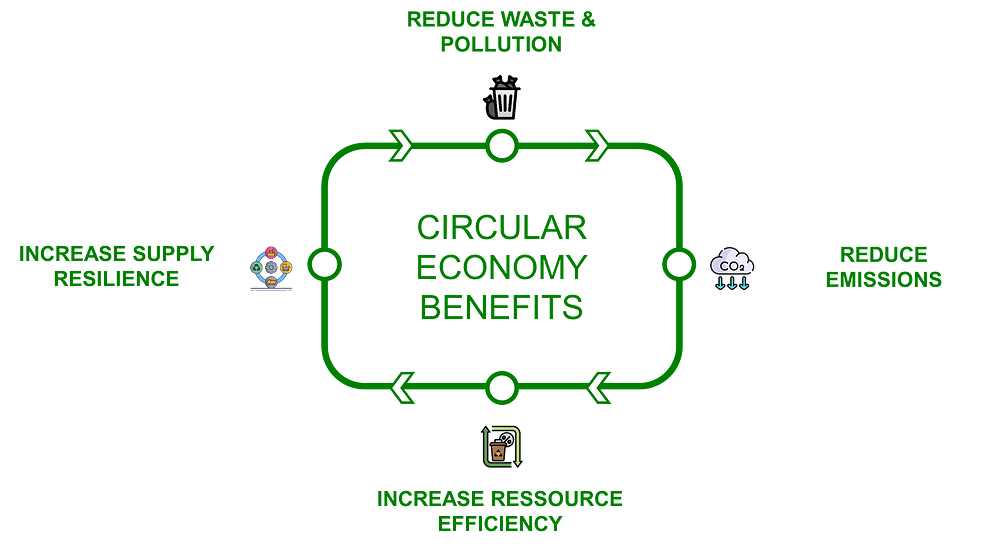

However, there are several environmental benefits that a fast fashion retail company could achieve by implementing circular economy principles.

- Reduced waste and pollution: reduce the amount of waste generated by your products and comply with current and future regulations

- Greenhouse gas emissions: decrease emissions to meet decarbonization targets

- Increase resource efficiency: reduce water and energy use to produce and deliver your products by recycling materials and products, reducing the need to extract new raw materials and energy.

- Increased resilience by reducing your dependence on finite resources and multiplying sources of raw materials supply with recycling

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.