Supply Planning using Linear Programming with Python

Where do you need to allocate your stock to meet customers demand and reduce your transportation costs?

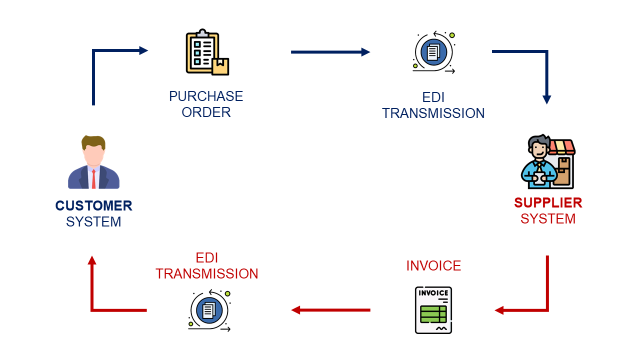

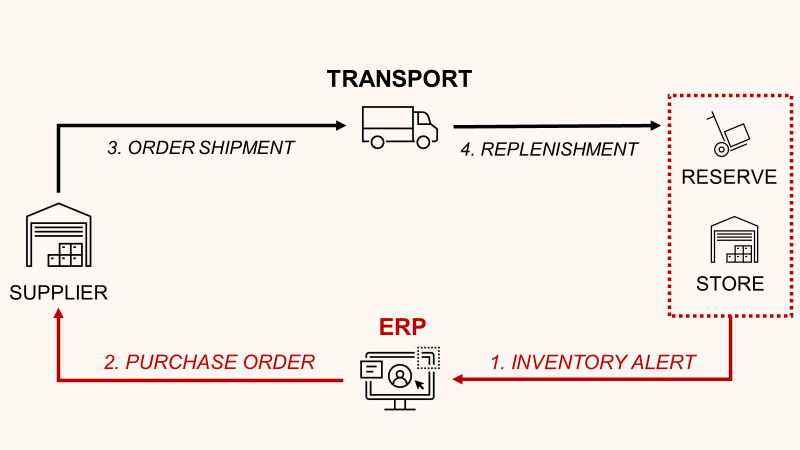

Supply planning is the process of managing the inventory produced by manufacturing to fulfil the requirements created from the demand plan.

Your target is to balance supply and demand in a manner to ensure the best service level at the lowest cost.

In this article, we will present a simple methodology to use Integer Linear Programming to answer a complex Supply Planning Problem, considering:

- Inbound Transportation Costs from the Plants to the Distribution Centers (DC) ($/Carton)

- Outbound Transportation Costs from the DCs to the final customer ($/Carton)

- Customer Demand (Carton)

💌 New articles straight to your inbox for free: Newsletter

I. Scenario

As a Supply Planning manager, you need to optimize inventory allocation to reduce transportation costs.

II. Build your Model

1. Declare your decision variables

What are you trying to decide?

2. Declare your objective function

What do you want to minimize?

3. Define the constraints

What are the limits on resources?

4. Solve the model and prepare the results

What are the results of your simulation?

III. Conclusion & Next Steps

Scenario

Problem Statement

As a Supply Planning manager at a mid-sized manufacturing company, you received feedback that distribution costs are too high.

Based on the analysis of the Transportation Manager, this is mainly due to the stock allocation rules.

In some cases, your customers are not shipped by the closest distribution centre, which impacts your freight costs.

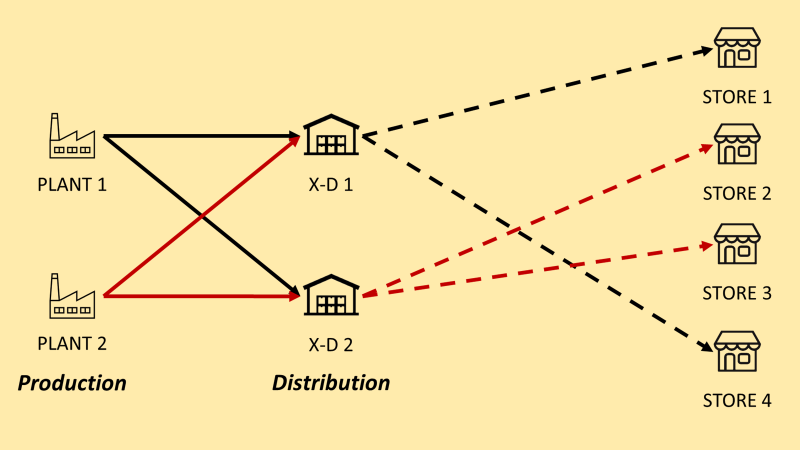

Your Distribution Network

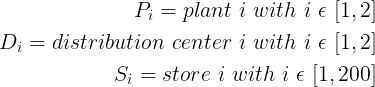

- 2 plants producing products with infinite capacity

- 2 distribution centres that receive finished goods from the two plants and deliver them to the final customers

- 200 stores (delivery points)

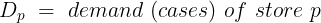

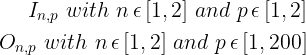

To simplify the comprehension, let’s introduce some notations

Store Demand

What is the demand per store?

You can download the dataset here.

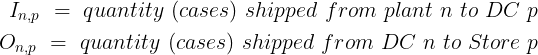

Transportation Costs

Our main goal is to reduce the total transportation costs.

This includes inbound shipments (from the plants to the DCs) and outbound shipments (from the DCS to the stores).

Which Plant i and Distribution n should I chose to produce and deliver 100 units to Store p at the lowest cost?

Let us start with some visualisations.

Build your Model

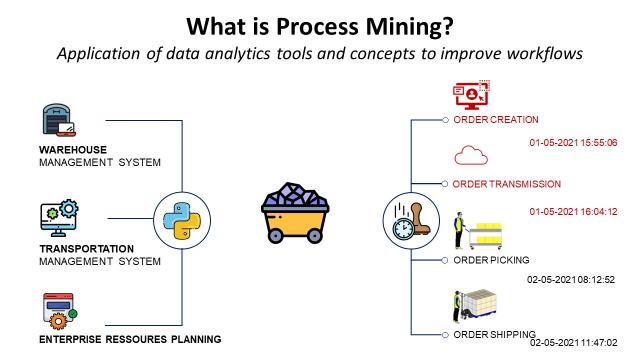

We will use the PuLP library in Python.

PuLP is a modelling framework for Linear (LP) and Integer Programming (IP) problems written in Python.

Declare your decision variables.

What are you trying to decide?

We want to decide the quantity of Inbound and Outbound transportation.

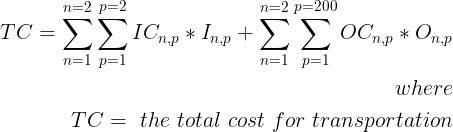

Declare your objective function

What do you want to minimise?

We want to minimise the inbound and outbound transportation costs.

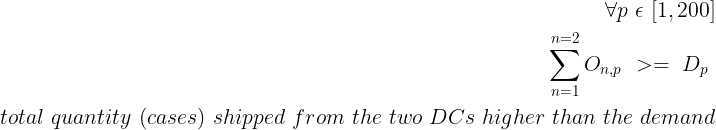

Define the constraints

What are the limits on resources that will determine your feasible region?

Supply from DCs must meet per-store demand

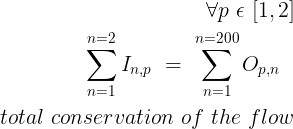

We don’t build any stock in the X-Docking platforms.

Solve the model and prepare the results

It is time to run the optimisation.

Result

The model takes the cheapest route for Inbound by linking P2 to D1 (resp., P1 to D2).

As expected, more than 90% of outbound traffic passes through D1 to minimise outbound costs.

Do you want to implement it?

Conclusion

This methodology allows you to perform large-scale optimization by implementing simple rules.

You will typically avoid having a store not delivered via the optimal route.

The model presented here can be easily improved by adding operational constraints:

- Production Costs in Plants ($/Case)

- Maximal X-Docking Capacity in Distribution Centres (Cartons)

But also by improving the cost structure by adding

- Fixed/Variable Costs Structures in Distribution Centres ($)

- Fixed + Variable Transportation Costs Structure y = (Ax +b)

The only limit you will find is the linearity of the constraints and the objective functions.

YOU CAN’T

- Implement a non-linear production costs rule = f(Cases) to simulate the economies of scale during the production process.

- Implement a non-linear (by range) transportation costs rule of total shipment size.

As soon as you try to touch the linearity of the objective function or the constraints, you leave the beautiful world of linear programming and face the pain of non-linear optimisation.

This is what we did in this article.

About Me

Let’s connect on LinkedIn and Twitter. I am a Supply Chain Engineer who is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimise your supply chain and meet sustainability goals, please contact me.