4 Smart Visualizations for Supply Chain Descriptive Analytics

Use Python to build visualizations that will provide visibility on key Supply Chain Metrics

Article originally published on medium.

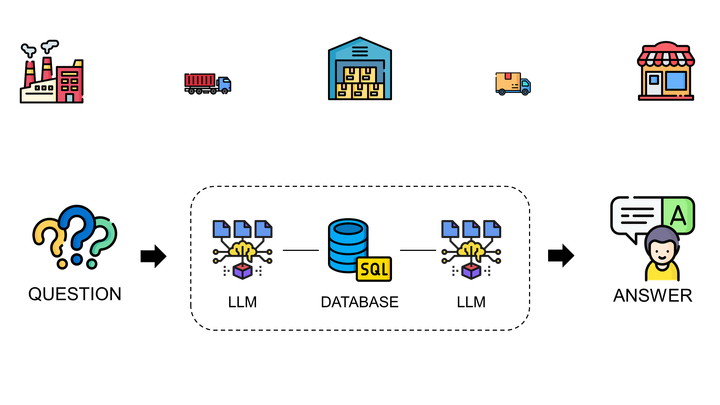

Supply chain Analytics can be defined as a set of tools and techniques your organization should use to get supply-chain operational insights from data.

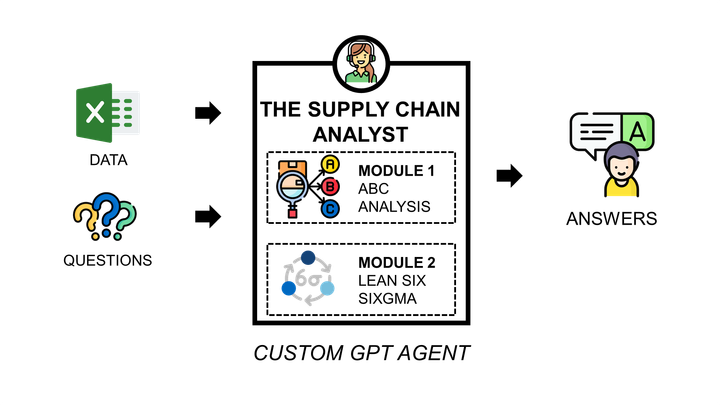

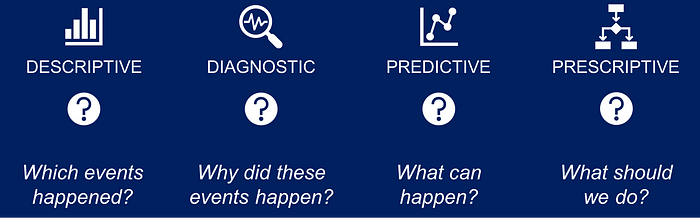

In a previous article, I defined the four types of Supply Chain Analytics that answer different types of operational questions.

It starts by building the foundation of Descriptive Analytics to monitor the present and analyze the past.

In this article, I will share four python smart visualizations for Descriptive Analytics that provide key insights to understand your Supply Chain.

💌 New articles straight in your inbox for free: Newsletter

If you prefer watching, check my Youtube tutorial!

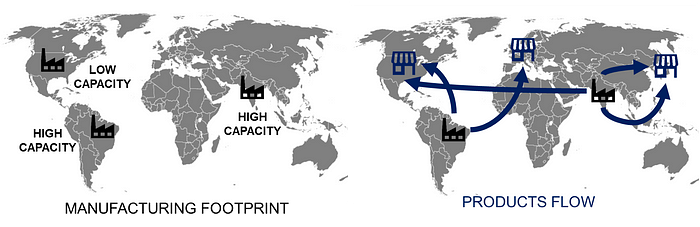

Supply Chain Network

A Supply Chain can be defined as a network of processes and stock locations built to deliver services and goods to customers.

The main drivers of your network optimization are the locations of your manufacturing sites and the optimization of the flows.

Supply Chain Flows

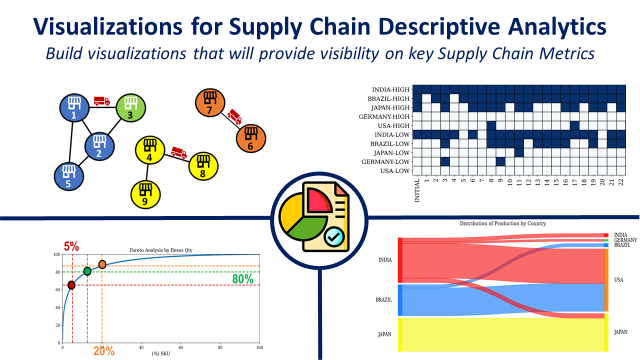

You want to have an understanding of the efficiency of your network by drawing the flows between production areas and markets.

In this single chart, you have visibility on all the different flows. On the left, you have the production facilities and on the right, you have the markets.

For more details, you can find the source code in my GitHub repository.

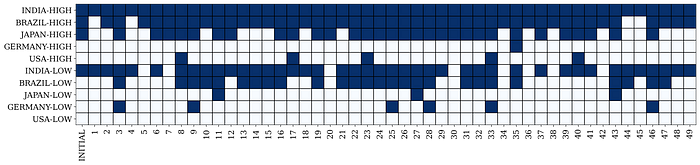

Network Design

Supply chain Network Optimization makes the best use of data analytics to find an optimal combination of factories and distribution centres to produce and deliver products at the lowest cost.

If your demand is unstable, you can run simulations for different scenarios and ask your model (based on linear programming) to provide the best solution for each of them.

A solution is basically a set of boolean decision variables listing all potential locations: their value is 1 if you open the location 0 else.

In this chart, you have visibility on the results of 50 different scenarios:

- x-axis: the name of the scenario

- y-axis: the decision variable linked to a facility (dark blue: open, white: closed)

For more details, you can find the source code in my GitHub repository.

Products Rotation

In Supply Chain Management, Product segmentation refers to the activity of grouping products that have similar logistics characteristics (like rotation).

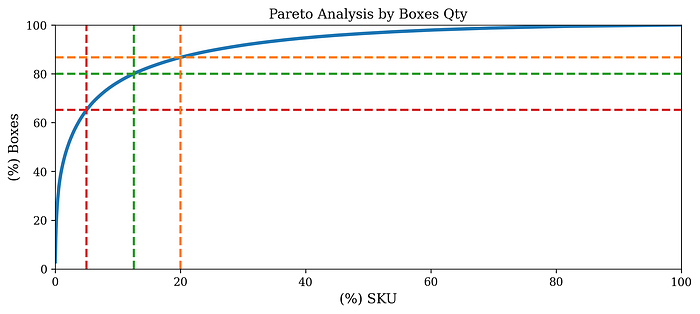

Pareto Chart

It is important to classify your products in order to allocate your efforts to inventory management, optimize your warehouse operations or design your racking layout.

The foundation of this approach is the Pareto principle or also called the 80–20 rule.

Most of the time, a minority of your products (usually around 20%) is making the majority of your outbound volumes (usually around 80%).

This plot can show you where your product rotations are compared to the Pareto law:

- x-axis: the percentage of reference of your portfolio (%SKU)

- y-axis: the percentage of the outbound volumes they represent (%Boxes)

In this particular example, you can quickly see that you have less than 20% of your total portfolio which contributes to 80% of the outbound volume.

For more details, you can find the source code in my GitHub repository.

Logistics Performance

The performance of your distribution network can be summarised in one sentence

Are you delivering your end customers on time in full?

This is the central question animating performance management with analytics, operational review and continuous improvement initiatives.

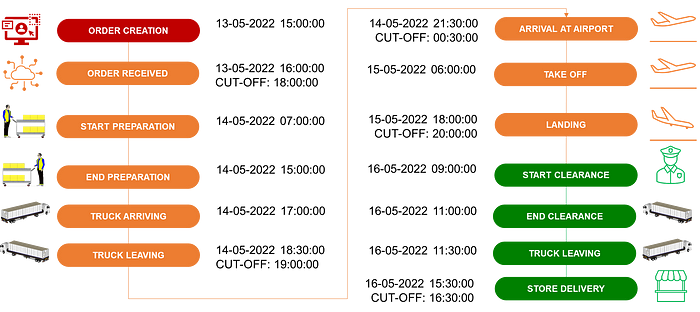

Shipment Tracking

Supply Chain Descriptive Analytics use the data generated by the different systems involved in your distribution chain to follow the timestamp of each step your shipment is going through.

At a tactical level, you have distribution planning teams that are following the status of the orders created recently.

From the order creation to the store delivery your shipment is going through different steps:

For each step, your systems are recording time stamps at the beginning and at the end of the process.

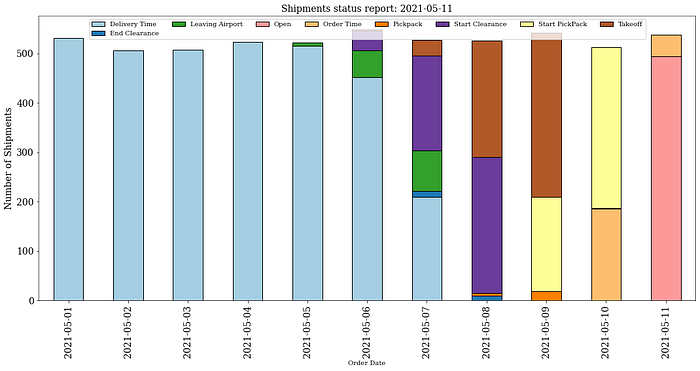

At a time t, this chart is showing the split of shipments by current status:

- x-axis: orders are grouped by order creation date

- y-axis: number of shipments

- legend: the current status of your shipment from order creation to store delivery

- 100% of the orders created before 05th May are delivered- A majority of the shipments created the 8th are blocked in the clearance

📈 DATA

You need to prepare a DataFrame by grouping orders by creation date and current status and count them.

📚 LIBRARY

You can use matplotlib.pyplot for a bar plot selecting stacked=true

For more details, you can find the source code in my GitHub repository.

Conclusion

These very simple charts can provide extremely valuable insights for supply chain design, optimization, and monitoring.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.