Inventory Management for Retail — Periodic Review Policy

Implement inventory management rules based on a periodic review policy to reduce the number of stores replenishments.

Implement inventory management rules based on a periodic review policy to reduce the number of stores replenishments

Article originally published on Medium.

Objective

Design inventory management rules that minimize the number of replenishments and meet stores demand.

Introduction

For most retailers, inventory management systems take a fixed, rule-based approach to forecast and replenishment orders management.

The objective is to build a replenishment policy that will minimize ordering, holding and shortage costs.

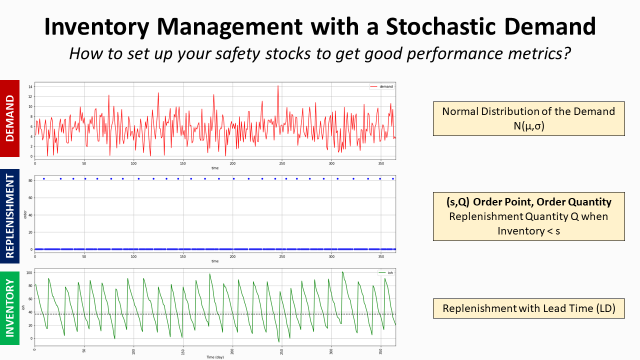

In a previous article, we have built a simulation model based on a continuous review inventory policy, assuming a normal distribution of the demand.

However, this kind of policy can be inefficient when you handle a large portfolio of items that may have different replenishment cycle lengths.

In this article, we will improve this model and implement a periodic review policy with Python to limit the number of replenishments.

💌 New articles straight in your inbox for free: Newsletter

I. Scenario

1. Problem Statement

As an Inventory Manager of a mid-size retail chain, you are in charge of setting the replenishment quantity in the ERP.

2. Limits of the continuous review policy

What is the impact a continuous review policy on the number of replenishments when you handle several hundred SKUs?

II. Periodic Review Policy: Order-Up-To-Level (R, S)

1. Introduction of the Inventory Policy

2. Definition of the Safety Stock3. How do you define k?

III. Example of Replenishment Policies

IV. Conclusion

I. Scenario

Inventory Management for Retail

As an Inventory Manager of a mid-size retail chain, you are in charge of setting the replenishment quantity in the ERP.

Because your warehouse operational manager is complaining about the orders frequencies, you start to challenge the replenishment rules implemented in the ERP, especially for the fast runners.

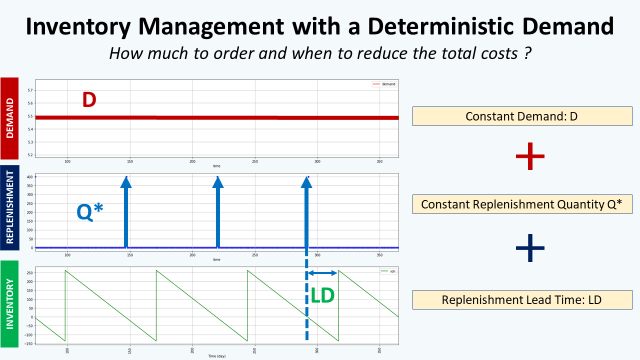

Previously, we implemented several inventory rules based on continuous review policies.

At each time t we check the inventory on hand (IOH):

Example for 1 SKU

We need 27 replenishment orders per year.

Question

How frequently do you need to order if you manage 2,294 SKUs?

2. Limits of the continuous review policies

We suppose that we only have 365 days of sales

- 10 stores (STORE_1, … STORE_10)

- 1 product family (FOOD_GROCERY)

- 2,294 unique SKU (STORE ID + PRODUCT FAMILY + ITEM CODE)

Simulation 1

Let’s implement the continuous review policy for 1 SKU

- SKU: STORE_1-FOOD_GROCERY_009

- Safety stock designed with k = 3

(3 times the standard deviation of the demand distribution) - Order Quantity: Q = 3 x Average_Annual_Sales

Comments

18 replenishments in the first 100 days

Simulation 2

What if we now have 10 SKUs to manage?

Comments

54 replenishments in the first 100 days

Simulation 3

What if we have 100 SKUs to manage?

Comments

935 replenishments in the first 100 days with less than 10 days without orders

Simulation 4

What if we have 2,294 SKUs to manage?

Comments

19,267 replenishments in the first 100 days (less than 10 days without orders)

With this method, the number of replenishments is exploding when you have a large portfolio.

Solution

We will build a replenishment policy using periodic reviews.

Periodic Review Policy: Order-Up-To-Level

Introduction of the Inventory Policy

To solve this issue of replenishment frequency, let us introduce a periodic review policy (s, Q)

- At each period R, the inventory on hand (IOH) level will be reviewed

- Stores will order to reach an inventory level of S

To simplify the comprehension, let’s introduce some notations:

Definition of the Order-Up-To-Level S

How to calculate the level S:

The level S is calculated to set the inventory to cover the need during the review period and the replenishment lead time.

How do you define k?

Your performance metrics will be directly impacted by the safety stock level

- You fix a target for any of the two metrics (e.g: I want the Cycle Service Level to be 95%)

- You calculate k to reach this target based on the distribution of your demand (Normal, Poisson)

- You fix your reorder point

Code

Example of replenishment policies

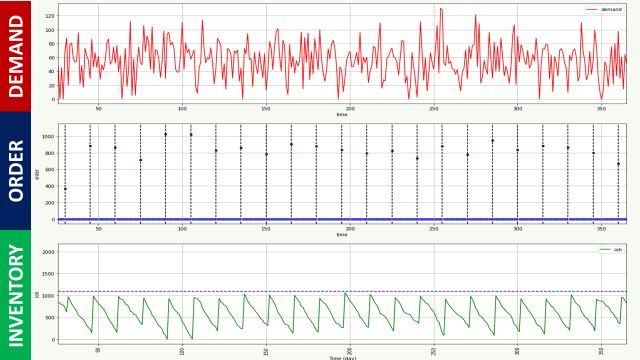

Example with SKU: STORE_1-FOOD_GROCERY_009

Review Period: R = 10 days

k = 1

Comments

10 replenishments vs. 18 replenishments in the first 100 days with 0 stock-outs

How many replenishments if you handle the full portfolio?

Comments

13,986 replenishments vs. 19,267 replenishments in the first 100 days with only 10 days of replenishments

Conclusion

After implementing a periodic review policy you will reduce your operating costs by

- Limiting the time windows of replenishments

This will optimize your resources for inventory management, order preparation and transportation management. - Reducing the number of replenishments

This will increase the quantity per replenishment and provide opportunities for shipment consolidations for stores delivered at the same time.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.